Services

With a combined experience of over 90 years in the precision machine tool industry the experienced staff in our repair department offer an extensive capability to assess and repair a wide range of precision mechanical and electromechanic components.

An extensive network of specialist suppliers and part stockists, coupled with in-house metrology, turning, cylindrical grinding and 4-axis milling equipment allow us to respond quickly to your requirements.

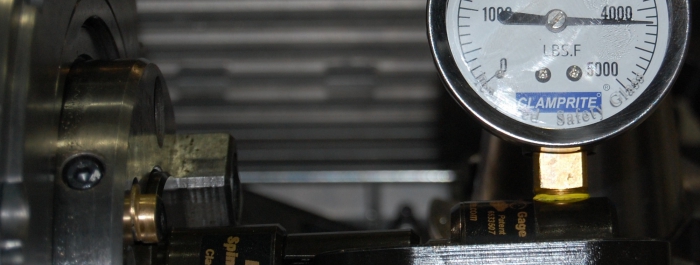

A wide ranging ball stock with bespoke and specialist equipment enable us to offer unique ball screw repair and refurbishment services which include ball nut regrinding, rapid replacement manufacture and full torque testing.

Spindle Repairs

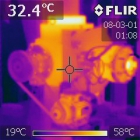

We perform run-in tests whilst monitoring bearing temperatures while the spindle bearings 'bed-in' following replacement.

The image below shows a large spindle head from a Dorries Scharmann DST BK2 Horizontal Mill (approx. 1000kg), which was completely overhauled with extensive replacement part manufacturing with new bearings and seals fitted throughout. This head had drive positioning errors caused by a heavily worn and damaged drive coupling which was re-manufactured.

Other images are from a Pietro Carnarghi Universal Head which had a catastrophic failure during operation. The spindles were fully stripped, new precision components were machined and replaced, new seals and bearings were fitted throughout & the draw bar was fully refurbished. Images show the universal head fully stripped, being reassembled, and tested using thermal imagery.